When professionals select windows or doors for use in buildings, they need to know how those windows will perform under hazardous weather conditions.

The performance grade (PG) rating and the design pressure (DP) rating are useful tools to help architects select a project’s windows. An architect can use them to decide on the most appropriate window choices for a particular project.

PG ratings and DP ratings are not equivalent. For example, the DP rating is simpler than the PG rating. The DP rating is only concerned with whether a product can withstand uniform loads caused by wind or (in the case of skylights) snow.

The PG rating is given to products that meet the industry standard’s performance requirements. AAMA/WDMA/CSA 101/I.S.2/A440-17, the North American Fenestration Standard, is commonly referred to as NAFS-17. It has four mandatory performance requirements:

- Resistance to air infiltration

- Resistance to water leakage

- Structural adequacy to withstand wind loads

- Resistance to forced entry

In addition to the performance requirements, auxiliary product-specific tests are done.

The test results determine the single structural class rating. The air, water and wind load tests indicate how much wind, water and structural load a window or door can withstand without failure. (A wind test only considers sustained winds. It doesn’t consider unpredictable events such as strong wind gusts, tornadoes, or debris that becomes a projectile because of the wind.)

I think that basic humanity is the same in most walks of life. One lady came up to me after a class. She asked me how the group could be in the business as long as they had been and not understand what I’d been teaching them at all. I realized then that longevity doesn’t make anyone an expert, no matter which industry they are in. It just means someone may have been doing something wrong for a long time.

Products are given a PG rating if they comply with all four mandatory performance requirements. Windows or doors with higher numbers can withstand more than windows with lower numbers. But since manufacturers for tests, they are selective about which windows they submit for testing.

After a window or door has been installed, the wind force is the main source of structural loading on it. Wind pressure is directly proportional to the square of the wind velocity.

Architects can calculate the design pressure for buildings to define the expected wind pressure on a building and the weight load capacity for individual building components that reinforce the building. The process involves considering the following variables when they determine which windows and doors meet the requirements:

- The expected wind at a specified location

- A building’s exposure type

- The building type

- The average height of the roof measured from eave to peak

- The wall and roof zones

Tell us about your background. How did you become a window expert?

I started in California in 1995, working with Simonton Windows. After working for many years as the western region sales manager, I desired to move back home to Salt Lake City and, in 2004, joined AMSCO Windows.

AMSCO has dealers in most of the western states, Kansas and Oklahoma, and has done some large projects all over the United States. I’ve had the opportunity to travel a great deal and meet many of our dealers. I have enjoyed teaching them and helping them with service issues, and developing relationships with builders.

What is the most interesting or surprising fact you’ve learned because of your work at AMSCO Windows?

Once I no longer had responsibility for specific dealers and began to work as an architectural rep, a whole new world opened up to me. I had to learn new words, codes, the concerns of architects and how to help them or be a resource for them. The class I teach, “Specifying Windows, Doors, and Skylights using Performance Standards,” has taught me the criteria one must master to build a structurally sound building as far as windows are concerned.

What advice would you give architects about choosing windows?

That’s what the one-hour class is all about.

Why is it important to choose windows based on design criteria? Doesn’t it make sense to prevent potential liability issues by installing windows with the highest ratings available?

Choosing windows with the highest possible ratings could be three times more expensive than choosing the window based on design criteria. Also, contractors may be reluctant to work on a project when they know they won’t make a profit because the windows’ cost takes too much of the project’s budget.

A better approach is to take the time to select the right window for the project. The window will function appropriately but cost less than one with a higher rating, which means contractors will be more willing to take on your project.

What if two windows have the same PG rating?

It means they performed the same during testing.

Are AMSCO’s windows built per NAFS-17?

Yes. We follow the standard.

How do you know what performance class is needed for a given job?

Calculate the building’s minimum design pressure. Choose the PG that exceeds the minimum design pressure.

What are the specific performance requirements for each class?

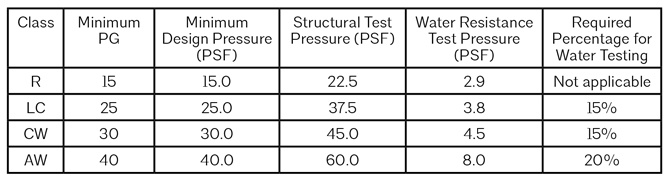

Entry into each performance class is based on a gateway, which is the minimum set of primary requirements for that class. The gateway is expressed as the design pressure or wind load in pounds per square foot, and products for each performance class have been designed and successfully tested for that pressure. For example, the gateway for class R is 15 PSF, or PG 15. For class LC, the gateway is higher: 25 PSF, or PG 25. If a tested product does not meet the 15 PSF requirement, it cannot be labeled R. If it does not meet the 25 PSF requirement, it cannot be labeled LC, and so on.

Refer to the following table for a list of performance classes, the associated PG and the other tests’ criteria.

- R buildings are one- and two-family dwellings.

- LC buildings are low-rise buildings that are typically multifamily, offices, professional buildings or motels.

- CW buildings are low- to mid-rise buildings that include hospitality, retail, and institutional use.

- AW buildings are high-rise buildings, larger institutional buildings and so on. They would include places where engineers and architects expect demanding fenestration use, such as skyscrapers or buildings that must continue functioning under emergency conditions.

The performance class designations are descriptive. They are not directly related to similar designations often found in building codes.

Some windows have gold-colored labels on the inside of the frame stating that they have been rated in accordance with AAMA/WDMA/CSA 101/ I.S. 2/A440-XX. What does this mean, and how do you read the AAMA Gold Label?

The label’s four key components are on the bottom line of the label’s right side and are separated by hyphens. They are:

- Performance class

- Performance grade

- The maximum size tested (in metric and inch-pound units)

- The window type: H (hung), C (casement), HS (horizontal slider) and so on

Is there more than one gold label type?

Yes. ANSI/AAMA/NWWDA 101/I.S. 2-97 is a voluntary performance specification for aluminum, vinyl and wood-framed windows and glass doors. The specification has standards for air leakage, forced-entry resistance, structural strength and water penetration. It also has some material and component requirements. NFRC 100 is a thermal performance standard.

These gold labels were divided into three sections by two vertical bars.

- The left section had the AAMA member logo.

- The middle section listed the manufacturer’s code number on the bottom right side.

- The right section consisted of five lines.

■ Line 2: the specification used to build the window

■ Line 3: information about the window (see below for more information)

■ Line 4: the manufacturer’s series number

■ Line 5: if necessary, any specific code compliance

The third line contained the following information:

- Window type: H (hung), C (casement), HS (horizontal slider) and so on

- Product class: R (residential), C (commercial), LC (light commercial), HC (heavy commercial) and A (architectural)

- Performance grade: 15, 20, 25, 30, 35 and so on

- Maximum size tested, such as 120 x 59

How important is it to protect a home or business with windows or doors that have PG ratings?

Very important, because you are shooting in the dark without them. If the PG value is too low, you risk catastrophic failure. If the PG value is too high, the window costs more than necessary.

What are the best DP or PG ratings for Utah?

That depends on where the building sits and how tall it is. Choose the windows that are appropriate for the situation. Architects don’t get into PG ratings for residential homes, but PG ratings are very important for multifamily homes. I use the same program architects use to define PG ratings.

Once I no longer had responsibility for specific dealers and began to work as an architectural rep, a whole new world opened up to me. I had to learn new words, codes, the concerns of architects and how to help them or be a resource for them. The class I teach, “Specifying Windows, Doors, and Skylights using Performance Standards,” has taught me the criteria one must master to build a structurally sound building as far as windows are concerned.

What about water tests?

Wind pressure tests are important, and that will continue, but so are water tests. California and Colorado already do them. Utah will do them, too. We are preparing for that by training people.

Do you have any specific information about windows you would like this magazine’s readers to know?

We have great products, and we don’t exaggerate or tell stories about them. People like to do business with us because we do our very best to take care of them.

I’ve had experience with window companies throughout the U.S.; we are conservative and financially sound. Some companies turn over their staff like hotcakes, but we have employees who have been with the company for 30 or 40 years. They are good people.